Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Warnings in the application of Galvanized Steel Sheet - animal husbandry risks

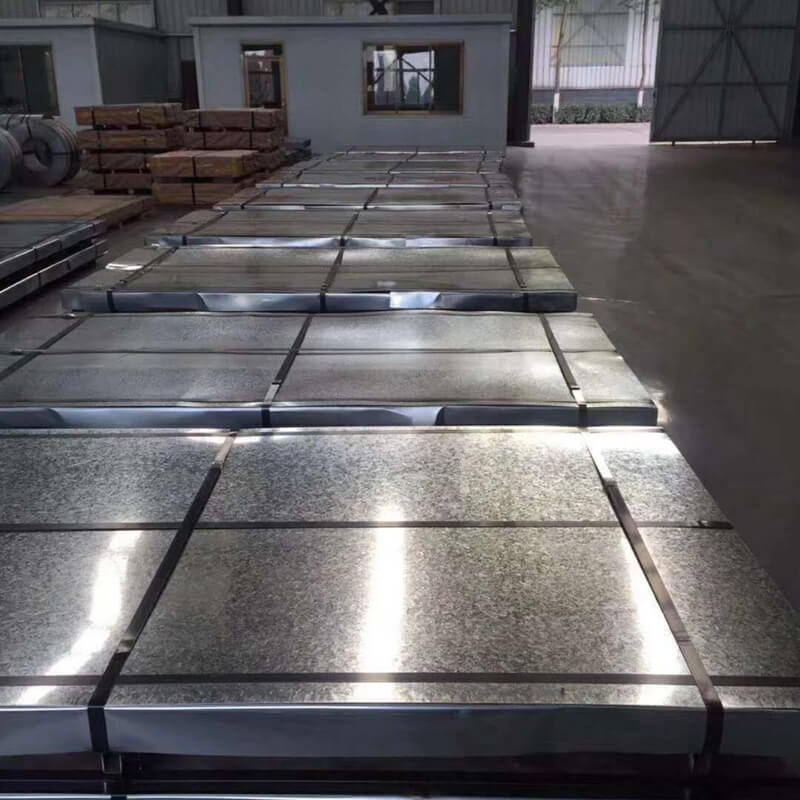

With the upgrading of manufacturing and the increase in the output of private galvanizing plants, the price of galvanized products has become cheaper and cheaper. Many applications that originally used pure zinc steel plates, such as workshops, ventilation ducts, and color-coated substrates, have begun to switch to use. Galvanized Steel Sheet. In Southeast Asia, Eastern Europe, Central and South America and other places, my country's export volume of galvanized steel sheet is also increasing year by year.

The galvanized steel sheet has excellent corrosion resistance. The salt spray test time of the 90/90 (unit: g/m2) coating product of ordinary pure zinc steel sheet is about 120 hours. Fog experiments can easily exceed 1200 hours.

Reasons for good corrosion resistance of aluminum-zinc salt spray test

The reason for the huge difference in the performance of gallium-zinc (55% aluminum, the rest zinc) and pure zinc (99% zinc) in the salt spray test is that the principle of corrosion protection is different.

Pure zinc: sacrificial protection, the zinc layer is preferentially corroded to protect the substrate, and the substrate can be well protected before the zinc layer is corroded.

Aluminum-zinc: partition + sacrificial protection, aluminum in the coating acts as a skeleton, and an alumina film is formed on the surface to cut off the corrosive medium; the zinc in the skeleton gap plays a role of sacrificial protection when the partition fails.

However, there are still some limitations in the application of aluminum-zinc coated steel plates. The industry generally believes that it is not suitable for use in animal husbandry greenhouses. Although aluminum-zinc coatings have excellent corrosion resistance in accelerated corrosion environments such as salt spray experiments, they are widely used. in the building. However, in the corrosive environment of buildings in some special industries, the corrosion resistance of aluminum-zinc coatings will be greatly reduced.

For example, in animal husbandry, especially in the construction of animal husbandry captive greenhouses, it is generally considered in the industry that it is not suitable to use aluminum-zinc-coated steel plates or color-coated steel plates with them as substrates. As shown in the picture below, the ceiling, light steel keel, doors and windows and other components of the pigsty are not recommended to be made of galvanized steel.

Reasons why aluminum zinc coating cannot be used in animal husbandry

The interior of animal husbandry greenhouses (captive buildings) is a highly corrosive environment. Not only does it have high humidity, but also various highly corrosive disinfectants are used. In addition, bacteria will decompose cattle, pigs or poultry into amines and acids. Among them, amines are one of the important reasons for the accelerated corrosion of aluminum-zinc coatings.

Due to the presence of aluminum in the coating, the resulting aluminum oxide film has very good acid resistance and can isolate the acidic corrosive atmosphere, but the amines decomposed in the coating are very corrosive to it.

When the aluminum that acts as a partition in the coating is gradually consumed, the zinc that acts as a sacrificial protection is exposed to a corrosive atmosphere and continues to perform sacrificial protection (protecting the Steel Plate by preferentially corroding itself). Since the main component of the aluminum-zinc coating is aluminum (55% aluminum), zinc is less than 45% (and a small amount of other elements), which means that the proportion of zinc in 90g/m2 aluminum-zinc products may be less than 40g/m2. The amount of galvanizing with a thickness of 40g/m2 on one side is usually used in applications where a thicker coating is required and the corrosion conditions are not harsh, such as automobiles (paint film 80~120μm), home appliances, etc. In the animal husbandry greenhouse, this small amount of zinc is quickly consumed by the corrosive atmosphere, and the subsequent substrate is **, which is quickly perforated and rotten.

Why is the color-coated steel plate of the aluminum-zinc-plated substrate not suitable?

Although there is a layer of corrosion-resistant coating on the surface of the color-coated steel sheet, the coating is usually relatively thin (usually about 20 μm), and 50 μm is already considered a thick coating. At present, only a few steel mills can produce 100 μm and thicker coatings. Coated sheet (eg Baosteel Co., Ltd.).

In addition, the paint film of the color-coated board is easily scratched and scratched during the process of pressing the tile, and the cross-sectional fractures of the color-coated board are all at the edge of the color-coated board, at the buckle interface, and at the fastener hole position. Exposed to the outside, it is difficult to carry out protective treatment, and corrosion at these positions will cause the color-coated plate coating to peel off and quickly fail. Therefore, in the animal husbandry captive greenhouse, the color-coated plate of the ordinary aluminum-zinc-plated substrate is usually not recommended.

So what materials are generally recommended in animal husbandry?

The anti-corrosion of animal husbandry buildings is a comprehensive subject, including the structural design of buildings, functional planning, drainage and ventilation, animal excrement disposal specifications, staff working habits and job regulations. customized. Among these factors, the anti-corrosion ability of building materials itself is only a part, and steel mills usually have some recommendations. Take U.S.STEEL (U.S. Steel United) as an example, they recommend using Z275/G90 (double-sided 275g/m2) pure zinc coating + phosphating sealing treatment, and at the same time need to do a good job such as incision section protection, moisture-proof film isolation, etc. auxiliary measures. It can be said that in livestock housing buildings, the building life is mainly determined by good design and not only building materials. (Of course, this suggestion is a bit old, when domestic and foreign steel mills have not yet developed products specifically for animal husbandry.)

What is the use of knowing this knowledge point?

To increase your knowledge points, of course, is to improve efficiency and reduce losses in the business. The user's risk is our risk, and we must think in advance what the user does not expect. Especially when doing export trade and large-scale supporting projects, we must develop the habit of asking clearly about the purpose and intervening in tracking. Grasp the key words of animal husbandry, amines, aluminum corrosion, aluminum-zinc color coating, special color coating for animal husbandry, etc., you will develop your own "business instinct" in the business. In the process of communication, these keywords will trigger our "business instinct" to realize the potential risks, by repeatedly reminding users, by adding disclaimers in the contract, and by recommending the loss of high-quality special products. In essence, only in this way can we better serve users and improve our competitiveness in the red sea of steel trade.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.